Frequently asked questions

General

You can find further details in the operating instructions in addition to the data on our website for the individual product groups. On request you can also obtain a detailed data sheet relating to a defined unit.

Our products are designed as standard from +5°C to +40°C. Moreover there are special versions for specific temperature ranges from -40°C to a maximum of +55°C. For special operating conditions we recommend you contact our customer consultants.

Compressor aggregate

The nominal pressure indicates a reference value for the pipework system. The value is indicated according to DIN, EN, ISO by using the abbreviation PN (Pressure Nominal) followed by a dimensionless whole number indicating the design pressure in bar at an ambient temperature of 20°C.

Dürr Technik compressors achieve a higher pressure than the indicated nominal pressure. The volume flow rate reduces at pressure rates above PN.

The compressors can be used up to the safety pressure (PS), which can be up to 12 bar - depending on the product series. The general principle is that higher pressure rates reduce the lifecycle.

By use of the oil-free technology our compressors are practically maintenance-free. We just recommend you exchange the intake filter every year.

The cupseal and the cylinder wear out depending on the application conditions. See more details for the exchange of these parts in our operating instructions.

The wear and tear of the carbon brushes depends on the ambient temperature, the start-up currents and the switching frequency. Usually they work for thousands of hours.

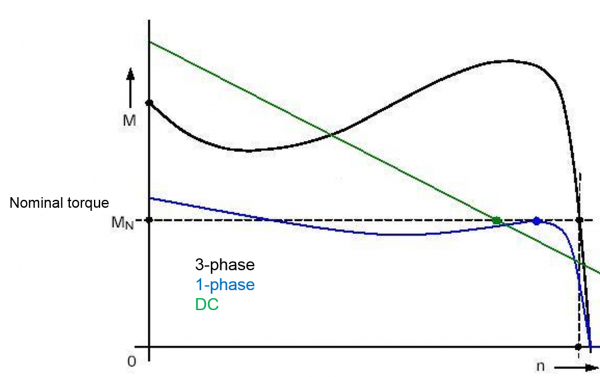

Electric motors (DC as well as AC motors) draw higher currencies on start-up, because in order to accelerate the rotating oscillator to nominal speed, more performance and consequently more current is needed than for keeping the speed. This higher switch-on current is referred to as start-up current.

Frequency converters / traction current converters are mainly used in the railway and vehicles sectors. Not every motor is suitable for VFD operation. Therefore, Dürr Technik offers a broad range of special units with a reinforced winding insulation of the motors. If you have any questions, please contact our customer consultants.

Compressor stations

Condensate is an unavoidable result of compressed air generation. This is created by the humidity contained in the intake air. On compression and the temperature rise relating to this, this humidity is initially present as vapour. After the compression there is only a small fraction of the original volume and oversaturation of the air occurs. When the air cools down, the humidity condenses.

The easiest and cheapest condensate drainage of the receiver/vessel is carried out manually. However, that often gets overlooked. Then, the pressure receiver fills up with condensate. The available receiver/vessel volume for storing the air is thereby reduced. That leads finally to more frequent start cycles. In this way, the lifecycle of the unit is shortened unnecessarily.

Therefore automatic drainage makes sense if there is no guarantee that someone will regularly drain the condensate manually. All our stations with the option „K“ (e.g. HA-062K) or with the DürrTronic electronic control system (e.g. WA-062C1) are available with such automatic condensate drainage.

The condensate drain valve opens every time the compressor is started/powered up and additionally on a regular basis at factory pre-set intervals.

Usually, compressors do not run against pressure. We therefore offer for stations a mechanical relief valve and time-controlled solenoid start-up valves. Thus, every time the system is switched off, it is also vented.

In case of short power interruptions or a short manual switching off and switching on while the compressor is running up, there is still pressure in the line on a mechanical start-up relief. The consequence is that the compressor does not run against pressure and the motor can become overheated. In this case the on/off switch at the pressure switch has to be pressed.

Dürr Technik offers comfortable automatic starting-up relief. Integrated in all stations with "A" (e.g. HA-160AK) and in stations with DürrTronic electronic control system (e.g. WA-062C1).

At the outlet of the compressor the compressed air is 100% saturated .

The role of a compressed air drying installation is to reduce the humidity which is contained in the compressed air, ensuring that no further condensate falls out.

The membrane drying system of Dürr Technik fully automatically supplies dry and clean air according to ISO 8573-1. The dried air is stored directly in the pressure receiver.

The compressor aggregates have to be fitted with intake filters. We offer a selection of filters for diverse models. The filter mesh of 2 or 3 microns protect the compressors optimally against dirt particles.

Our membrane drying installations are fitted with a sinter filter and a second filter with 3µm as standard. As an option a fine filter with 0.01 µm is available. Further information can be seen in the following chart.

The norm ISO 8573-1:2010 classifies the quality or purity of compressed air. The classification of the air is made by determining a certain maximum concentration of pollutants allowed in the air. Particles, water and oil are considered to be pollutants. Each class has a defined maximum value for these three materials. The classes range from 0 to 9 – in addition there is also class X.

The higher the classification number, the lower the purity required.

| Solid material / dust* | ||||||||

|---|---|---|---|---|---|---|---|---|

| Max. particle count per m3 of particles with d (μm) | Humidity ** Pressure dew point / | Total oil content | ||||||

| Classification | ≤ 0,1 | 0,1 <d ≤ 0,5 | 0,5<d ≤ 1,0 | 1,0<d ≤ 5,0 | μm | mg/m3 | x=proportion of water in g/m3 fluid | mg/m3 |

| 0 | Specified according to application and better than 1 | |||||||

| 1 | - | 100 | 1 | 0 | - | - | ≤ -70°C | ≤ 0,01 |

| 2 | - | 100.000 | 1.000 | 10 | - | - | ≤ -40°C | ≤ 0,1 |

| 3 | - | - | 10.000 | 500 | - | - | ≤ -20°C | ≤ 1,0 |

| 4 | - | - | - | 1.000 | - | - | ≤ +3°C | ≤ 5,0 |

| 5 | - | - | - | 20.000 | - | - | ≤ +7°C | - |

| 6 | - | - | - | - | ≤ 5 | ≤ 5 | ≤ +10°C | - |

| 7 | - | - | - | - | ≤ 40 | ≤ 10 | x ≤ 0,5 | - |

| 8 | - | - | - | - | - | - | 0,5 ≤ x ≤ 0,5 | - |

| 9 | - | - | - | - | - | - | 5,0 ≤ x ≤ 10,0 | - |

* measured according to ISO 8573-4 respectively 8573-2 and 8573-5; reference conditions: 1 bar absolute, 20°C, 0% r.F.

** measured according to ISO 8573-3; reference conditions: 7 bar operating pressure, 20°C

As regards the particle size, we achieve class 1 by applying our fine filter with 0.01 µm. This filter is optional for the dryer stations.

By using the membrane dryer we achieve up to class 3 (Dew point - 20°C to 7 bar) regarding the water content, depending on the delivery rate of the compressors..

With our oil-free compressors we achieve class 1 regarding the oil content.